What are structural rivets?

Structural blind rivets (structural blind rivets) are specially designed rivets that have a locking mechanism to hold the mandrel in place. Before we discuss how exactly structural blind rivets work, we should first understand how blind rivets generally work.

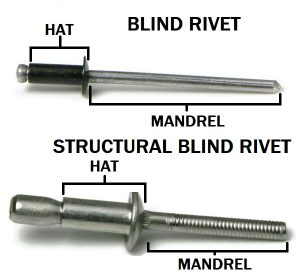

Blind rivets consist of two parts: the rivet cap and the mandrel. The rivet cap is the part of the rivet that deforms and remains in the installation. The mandrel is the part of the rivet that is pulled into the rivet and mostly removed. Standard blind rivet mandrels have a design flaw near the bottom of the mandrel that makes them more likely to break.

To install the rivets, you first need to drill a hole in both materials. The hole should be just wide enough to accommodate the rivet cap. Once the rivets are set in both materials, use a rivet installation tool to pull the mandrel through the back of the hat while pressing the hat firmly against the mounting surface. As the mandrel is pulled into the hat, it deforms the back of the hat, making it wider and pulled firmly against the back of the mounting surface. Once the torque is reached, the weak point of the mandrel snaps, completing the rivet installation.

How Do Structural Rivets Work?

Structural rivets work slightly differently than typical blind rivets. Structural blind rivets have a built-in (internal) locking mechanism designed to secure the mandrel inside the rivet after the exposed portion breaks off. This is often called a double locking rivet. Note in the photo to the right that the portion of the structural rivet's mandrel to the left of the cap is also much larger than in a standard blind rivet.

There are several reasons why structural rivets lock the mandrel inside the hat after installation:

Increase shear strength

Increase pullout strength

Higher vibration resistance

In some cases, they are said to be considered weatherproof as well

How To Install Structural Rivets

Installing a structural blind rivet can be done basically the same way as installing a standard pop rivet:

1. Line up the two installation materials

2. Choose the appropriate drill bit to match the diameter of the structural rivet

3. Drill a hole through both materials

4. Insert the rivet through both materials into the hole

5. Attach a rivet installation tool onto the mandrel

6. Activate the tool to draw the mandrel out towards the installation surface

7. Once the mandrel snaps it is completely installed

How To Remove Structural Rivets

Removing a structural rivet is just as simple as removing a standard blind rivet. To remove a structural rivet:

1. Punch a starting hole into the center of the rivet

2. Get a drill bit that is the same diameter as the hole originally drilled

3. Add some lubricant to the drill bit

A. *If the rivet is spinning, cover it in tape to prevent it from spinning

4. Drill through the rivet with the drill bit until it goes completely through the hole

Common Industry Uses For Structural Rivets

· Commercial Vehicles

· Sheet Metal

· Electrical

· HVAC

· Agricultural Equipment

Copyright © 2021 Wuxi Zhuocheng Mechanical Components Co.,Ltd. - All Rights Reserved.