A guest called our company and asked about our production experience, machines and testing equipment, and have you supplied water heater accessories? Our company just have this experience, we have cooperated with Italian famous company and showed some product photos for checking.

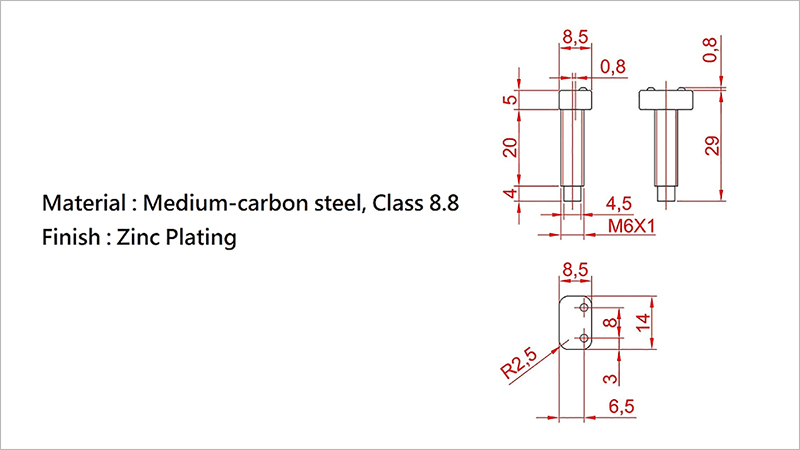

The guest is more confident to cooperate. Specially, there is a T-shaped screw with high material requirement, otherwise the head cracks during producting, and we must use good materials imported from Taiwan. Our company tries our best to get materials, but the cost is very high, so we need to reduce the cost through reducing the production process and forming the product at one time, it is required that the machines should be multi station and the molds should be accurately combined.

This is a non-standard screw, which we take seriously, summarize and analyze. First, open the grinding tool at the porous position, shrink the tail at the back, and cold heading at the porous position for one-time forming. The second is to select materials. We use 1008 materials for heat treatment and surface carbon generation. The third is that we spot check 50 of each batch number and follow up the whole process. Finally, we use the screening system to strictly screen the product quality.

Our engineers studied for a month and finally bought a multi station machine to produce. The samples are finished smoothly, the size is exact, the surface is flat, also the cost is reduced. The guest is very satisfied and directly arrange long-term order purchase.

Copyright © 2021 Wuxi Zhuocheng Mechanical Components Co.,Ltd. - All Rights Reserved.